In the realm of continuous improvement, lean manufacturing, and quality assurance, the concept of mistake-proofing, or Pokayoke, has emerged as a powerful technique to prevent errors at the source and ensure the seamless flow of processes. This article delves into the history, background, types, methods, approaches, and benefits of Pokayoke, shedding light on its significance in various industries and its ability to enhance operational excellence.

The Evolution of Pokayoke: A Journey of Error Prevention

The history of Pokayoke, the technique of mistake proofing, is a testament to the continuous pursuit of excellence in manufacturing and process improvement. Rooted in the principles of minimizing errors and enhancing efficiency, Pokayoke has evolved from its humble beginnings to become an integral part of quality management systems worldwide.

Origins and Shigeo Shingo:

The concept of Pokayoke finds its origins in Japan, where it was introduced as a key element of the Toyota Production System (TPS) in the 1960s. Shigeo Shingo, a revered Japanese industrial engineer and manufacturing expert, played a pivotal role in developing and popularizing the idea. Shingo recognized that many defects in manufacturing were a result of human errors, and he envisioned a methodology that would eliminate the possibility of these errors occurring in the first place.

Early Influence and “Zero Defects”:

During his work with Toyota and other Japanese manufacturing companies, Shingo emphasized the importance of building quality in the process rather than relying solely on inspection to catch defects. His philosophy aligned closely with the “Zero Defects” approach, which gained prominence in the 1960s. The idea behind “Zero Defects” was to create an environment where defects were unacceptable and every process was designed to ensure error-free production.

Birth of Pokayoke:

Shingo coined the term “Poka-yoke,” which can be roughly translated from Japanese as “mistake-proofing” or “error-prevention.” The term “Poka” refers to “inadvertent errors,” and “Yokeru” means “to avoid.” This term encapsulated the core philosophy of the technique – to design processes and systems that would prevent mistakes from occurring.

Early Examples:

Shingo and his colleagues began implementing Pokayoke techniques in various manufacturing processes. Early examples included simple mechanisms that prevented incorrect parts from being used or incorrect assembly procedures from being performed. For instance, he developed a method in which a worker would need to perform a specific action to ensure that a part was correctly oriented before it could be inserted into the assembly.

Contact, Fixed Value, and Motion-Step Methods:

Shingo categorized Pokayoke techniques into various methods. These included the “Contact Method,” which relied on physical interactions to prevent errors; the “Fixed Value Method,” which used specific limits to dictate process progression; and the “Motion-Step Method,” which ensured that steps were completed in a specific sequence. These methods formed the foundation for mistake-proofing systems.

Global Influence and Beyond Manufacturing:

As the principles of Pokayoke gained recognition and success in the manufacturing world, their influence expanded beyond the automotive industry. Other sectors, such as healthcare, electronics, and service industries, adopted the concept to improve quality, reduce errors, and enhance customer satisfaction. The essence of mistake-proofing was universally applicable, regardless of the domain.

Modern Integration and Technological Advancements:

With the advent of advanced technology, Pokayoke techniques have evolved to incorporate sensors, automation, and sophisticated error detection mechanisms. These innovations have made it possible to implement more intricate mistake-proofing solutions, allowing organizations to prevent errors with a higher degree of accuracy and efficiency.

Types of Pokayoke

There are several types of Pokayoke systems that organizations can implement to prevent errors and enhance operational efficiency. Let’s delve into these types with detailed examples for each:

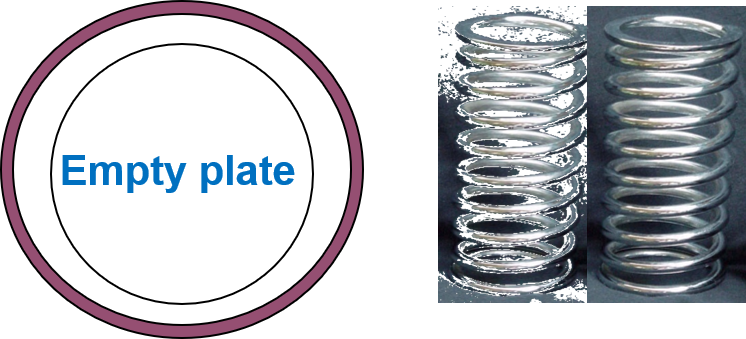

- Contact Method Pokayoke:

This type of Pokayoke system uses physical contact or a mechanism to prevent errors. It relies on a physical interaction that is either required or prohibited to ensure the correct execution of a process.

Example: In a manufacturing setting where parts need to be assembled in a specific orientation, a contact method Pokayoke can be implemented using a specially designed fixture. The fixture ensures that the part can only be inserted in the correct orientation, preventing assembly errors.

- Fixed Value Method Pokayoke:

This type of Pokayoke system sets a fixed value or limit that must be met for a process to proceed. It ensures that a certain condition is met before moving forward.

Example: Consider a bakery where bread loaves are baked. To ensure that the loaves are properly baked, a fixed-value Pokayoke can be employed by using a timer. The oven’s timer is set to a specific time that corresponds to the required baking duration. When the timer reaches zero, it triggers an alarm, signaling that the bread is ready and preventing undercooked products from being removed prematurely.

- Motion-Step Method Pokayoke:

This type of Pokayoke system focuses on the sequence of steps in a process. It ensures that each step is completed before the next step can be initiated, minimizing the possibility of errors due to incorrect sequencing.

Example: In an industrial packaging line, products need to be labeled before being sealed in boxes. A motion-step Pokayoke can be applied by implementing a sensor that detects whether the labeling step has been completed. Only when the label is detected can the machine proceed to the sealing step, preventing boxes from being sealed without labels.

- Fixed Sequence Method Pokayoke:

This type of Pokayoke system ensures that steps are performed in a predefined sequence. It prevents errors by enforcing a specific order of actions.

Example: Imagine a software development process where code is reviewed before being committed to the repository. A fixed sequence Pokayoke can be established by requiring that the code review is completed before the commit is allowed. This prevents developers from committing code without proper review, reducing the likelihood of introducing bugs into the codebase.

- Size and Shape Method Pokayoke:

This type of Pokayoke system ensures that components or materials have the correct size or shape before they are used in a process. It prevents errors related to incorrect sizing or shape discrepancies.

Example: In a pharmaceutical manufacturing facility, pills are dispensed into blister packs. To prevent errors caused by variations in pill size, a size and shape Pokayoke can be implemented using a mechanism that checks the dimensions of each pill as it is dispensed. If any pill deviates from the required size, the machine is automatically halted, preventing defective blister packs from being produced.

- Count Method Pokayoke:

This type of Pokayoke system verifies the correct number of components in a process, preventing errors caused by incorrect quantities.

Example: In an electronics assembly line, circuit boards are populated with components. A count method Pokayoke can be implemented by incorporating a sensor that counts the number of components placed on the board. If the sensor does not detect the correct number of components, the assembly process is halted, preventing incomplete or overpopulated boards.

Pokayoke systems, regardless of their type, play a vital role in error prevention and process improvement across various industries. By understanding the nature of potential errors and designing mechanisms to counteract them, organizations can enhance product quality, reduce waste, and foster a culture of continuous improvement.

Benefits of Pokayoke

The implementation of Pokayoke techniques offers numerous benefits to organizations across various industries:

Reduced Defects and Errors: By preventing errors from occurring or detecting them early, Pokayoke minimizes defects, leading to higher product quality and customer satisfaction.

Increased Efficiency: Mistake-proofing streamlines processes by eliminating rework and corrective actions, leading to improved efficiency and reduced waste.

Cost Savings: Fewer defects and errors translate to lower costs associated with scrap, rework, warranty claims, and customer complaints.

Employee Empowerment: Pokayoke empowers employees to take ownership of quality by actively participating in the design and implementation of error-proofing solutions.

Culture of Continuous Improvement: Embracing mistake-proofing encourages a culture of continuous improvement, where employees are motivated to identify and address potential issues proactively.

Real-World Example: Automotive Industry

Consider the automotive industry, where Pokayoke techniques have significantly impacted quality and efficiency. One prime example is the use of connectors with unique shapes that fit only into corresponding receptacles, preventing incorrect connections during assembly. This not only reduces the likelihood of defects but also enhances assembly line efficiency as workers can quickly identify the correct components to use.

Conclusion

Pokayoke, the art of mistake-proofing, has evolved from a visionary concept introduced by Shigeo Shingo into a cornerstone of quality management across industries. By incorporating prevention and detection-based techniques, organizations can ensure that errors are minimized at the source and that processes operate smoothly.

With benefits ranging from enhanced product quality to cost savings and a culture of continuous improvement, Pokayoke stands as a testament to the power of proactive error prevention in achieving operational excellence. As industries continue to evolve, the principles of mistake-proofing will remain a crucial tool in the pursuit of perfection.

Excel your career with the Online Six Sigma course

Six Sigma Courses from ‘Quality HUB India’

- Six Sigma White Belt (FREE) -E Certificate Available

- Lean Six Sigma Yellow Belt (LSSYB) Hindi Version

- Lean Six Sigma Yellow Belt (LSSYB) English Version

- Lean Six Sigma Green Belt (LSSGB) Hindi Version

- Lean Six Sigma Green Belt (LSSGB) English Version

- Lean Six Sigma Black Belt (LSSBB) Hindi Version

- Lean Six Sigma Black Belt (LSSBB) English Version

Other Relevant Courses from ‘Quality HUB India’

- Certified Quality Manager

- Certified Operational Excellence Manager

- Certified Quality Inspector

- Certified lean Expert Gold-Level 3

- Certified Minitab Expert

- Certified 5S Expert

- Certified KAIZEN Expert

- Certified Internal Auditor (ISO9001)

- Certified Internal Auditor (IATF16949)

- Certified Internal Auditor (EHS -ISO14001 + ISO45001)