What is Production Management?

Production management refers to the process of planning, organizing, directing, and controlling the activities involved in the production of goods or services. It encompasses all the tasks and decisions necessary to ensure the efficient and effective utilization of resources to meet production goals.

The Objective of Production Management

The primary objective of production management is to convert raw materials, labor, and other inputs into finished products or services in the most efficient and cost-effective manner. It involves overseeing various aspects, including production planning, scheduling, inventory management, quality control, and maintenance of equipment and machinery.

Strategic Decision-Making:

Production management entails strategic decision-making to determine the optimal production methods, processes, and technologies to achieve desired outcomes. It involves setting production targets, allocating resources, and designing workflows to ensure smooth and continuous operations. This includes forecasting demand, estimating resource requirements, and developing production plans that align with customer needs and market trends.

Organizing:

Organizing is a key aspect of production management, involving the arrangement of resources, personnel, and equipment to facilitate production activities. This includes establishing workstations, assigning tasks, and creating a suitable layout to maximize efficiency and minimize wastage of time and resources. Effective organization ensures that the right people and materials are available at the right time and place.

Direction:

Direction and control play a vital role in production management. Managers provide leadership, guidance, and supervision to ensure that production activities are carried out as planned. They monitor progress, track performance, and make necessary adjustments to maintain productivity and meet production targets. Control mechanisms, such as quality control measures and performance metrics, are employed to ensure that production processes adhere to set standards and specifications.

Responsibilities of Production Manager

The production manager is responsible for overseeing the manufacturing process within a company. Their primary role is to ensure that the production process runs smoothly and efficiently, meets the company’s production targets, and produces products of high quality. Some of the specific responsibilities of a production manager may include:

- Developing production schedules and coordinating with other departments to ensure timely delivery of materials and finished products.

- Monitoring and managing the production process to ensure quality, efficiency, and safety.

- Implementing and improving production processes to increase efficiency and reduce waste.

- Managing the production budget and ensuring that all costs are kept within budget limits.

- Hiring and training production staff and ensuring that they have the necessary skills and knowledge to perform their jobs.

- Evaluating and improving employee performance to ensure that production targets are met.

- Maintaining and repairing production equipment to ensure that it is in good working order.

- Ensuring compliance with health and safety regulations and other legal requirements.

- Identifying areas for improvement in the production process and implementing changes to improve efficiency and quality.

- Developing and implementing production policies and procedures to ensure consistency and efficiency in the manufacturing process.

Recommended Skills For Production Manager

As a Production Manager, you will be responsible for overseeing the manufacturing process of a company. To succeed in this role, you will need a range of technical and soft skills. Here are some recommended skills for a Production Manager:

- Technical knowledge: You need to have a strong understanding of the manufacturing process, production methods, and equipment. Knowledge of lean manufacturing principles, Six Sigma, and other quality control methodologies is also essential.

- Leadership skills: You will be responsible for managing a team of workers, so you need to have strong leadership skills, including the ability to motivate and inspire employees.

- Communication skills: You will need to communicate effectively with a range of stakeholders, including suppliers, customers, and employees. Excellent written and verbal communication skills are essential.

- Problem-solving skills: You will need to be able to identify and solve problems quickly and efficiently. This will involve working with others to find solutions and making decisions under pressure.

- Organizational skills: You will need to be highly organized and able to manage multiple projects at once. You should be able to prioritize tasks and manage your time effectively.

- Attention to detail: You will need to pay close attention to detail to ensure that the manufacturing process runs smoothly and that products meet quality standards.

- Technical writing skills: You may need to write technical reports, instruction manuals, and other documents related to the manufacturing process. Strong technical writing skills are essential.

- Analytical skills: You will need to analyze production data to identify areas for improvement and make decisions based on that data.

- Budgeting and financial management: You will need to manage production costs and ensure that projects are completed within budget.

- Adaptability: You will need to be able to adapt to changing circumstances and handle unexpected challenges that arise during the manufacturing process.

How to enhance your skills:

Professional courses related to production can be highly beneficial in a number of ways. Here are a few ways in which production professional courses can benefit individuals:

- Enhance Knowledge and Skills: Production courses can provide individuals with a deeper understanding of the production process, including planning, scheduling, inventory management, quality control, and more. This knowledge can help individuals develop skills that are essential in the production industry.

- Improve Career Opportunities: Production courses can help individuals develop specialized skills and knowledge that are in high demand in the job market. This can improve their chances of finding a job in the production industry or advancing in their current job.

- Increase Earning Potential: Professionals who have completed production courses may be eligible for higher-paying jobs due to their specialized skills and knowledge. This can lead to an increase in earning potential and financial stability.

- Network with Professionals: Production courses often provide opportunities to network with other professionals in the industry. This can help individuals build relationships with others in their field and potentially lead to job opportunities or collaborations.

- Stay up-to-date with industry trends: The production industry is constantly evolving and changing. Professional courses can help individuals stay current with the latest trends and technologies in the industry, which can give them a competitive edge.

Conclusion:

In summary, production management involves overseeing the entire production process, from planning to execution, to ensure efficient utilization of resources, meet production goals, and deliver high-quality products or services. It requires a combination of strategic decision-making, organization, direction, and control to optimize operations and achieve operational excellence in a competitive marketplace.

Continuous improvement is an essential aspect of production management. By monitoring performance, identifying bottlenecks, and implementing process enhancements, organizations can strive for operational excellence. Production managers employ various techniques, such as lean manufacturing, Six Sigma, and Kaizen, to eliminate waste, improve quality, and enhance overall efficiency.

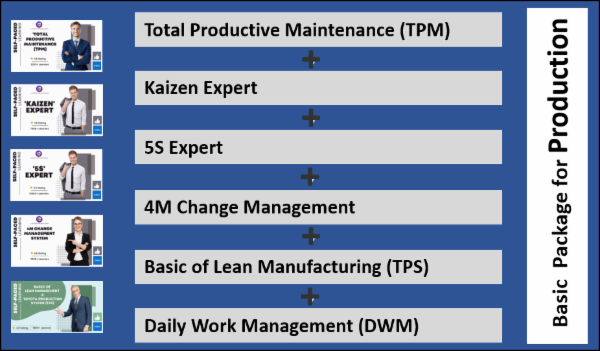

Quality HUB India offered Best Production Management Certification Courses

Hindi Version:

- Basics of Lean Management and TPS

- Lean Expert Silver (Level 2)

- Lean Expert Gold (Level 3)

- 5S Expert

- KAIZEN Expert

- Advanced Value Steam Mapping (A-VSM)

English Version:

Related Articles:

What is TPM? How to Implement TPM? Benefits of implementing TPM. Best TPM Books